A state-of-the-art 1911 carry gun from a master pistolsmith!

When it comes to the world of guns, Terry Tussey has pretty much “been there and done that” and then he wore out the T-shirt! You’d guess him as much younger, but as Terry approaches his middle 60’s he is capping a career in the gun business that begins with many years as a Colt representative, in addition to working for several other firms. He was one of the original practical/combat competition shooters in the “Leatherslap” days at Big Bear Lake in California with Jeff Cooper; and then finally, his many years as a well-known pistolsmith.

Tussey originally became known in law enforcement circles around Orange County, California, but word soon spread east and up and down the coast, and from there he began accepting work for officers from all over the country.

When civilian shooters found out that this perfectionist was available they flocked to his shop. The input and requests from this new group of shooters eventually led to “some experimenting”, and soon Terry was building compensated raceguns.

He didn’t sponsor any well-known shooters, and none of his guns ever won a national championship, but the experience was quite valuable, as Tussey developed his own comp system that is integrated into the existing slide he calls it the “StealthComp”.

The trek continued, and soon Tussey became interested in the Officer’s Model 1911. He set out to see how much he could trim off the little gun in both size and weight.

The process was evolutionary, but the results are certainly revolutionary, as Terry was able to shrink the slide of the gun from 6 1/8 inches to 5 5/8 inches. He also reduced the height of the gun from 5 3/4 inches to 4 7/8 inches without any loss of ammo capacity thanks to hand-made magazines.

The guns are not only small, they are also reliable, which is not always the case with a “chop job”. In this case, Tussey is a student of the 1911 and can quote not only the history of the gun but also the dimensional changes that have marked the life of the 1911.

I have been a customer (and friend) of Terry’s for many years now, and sometime over four years ago I got a hankerin for a new StealthComp carry gun built on a lightweight Commander.

(Having just spent some time telling you all about Terry’s mini 1911s I suppose I should explain that my hands are so large I am much more comfortable with a full-sized frame. To me, the control and the extra round of ammo make up for the extra inch of grip when trying to conceal the pistol.)

We ordered in the slide and frame from Caspian, I did the state registration paperwork on the receiver, and the project was put into motion . . . sort of.

I guess you could say that progress on the gun was sluggish at first, and then it slowed down from there.

Seriously, what happened is that every time Terry was ready to tear into the gun he would simultaneously come up with something new that he had been tinkering with to fruition.

There were two new methods to better support the StealthComp and muzzle portion of the top end, two new methods to further lighten the already lightweight gun, and a few other issues such as Tussey moving out of California after having lived there his entire 62 years (at the time)

Terry has also begun doing a round-butt conversion on the 1911.

This process has been a specialty of pistolsmith Ed Brown’s for some years now, and he even offers a jig so that others may do the job.

To the best my knowledge, Brown does not do the conversion on lightweight (alloy) frames, probably because they vary so much in specifications and size in comparison to the steel units.

Terry does his round-butts by hand, which gives him the control needed to do the lightweight frames without cutting through them.

Anyway, this sequence of events strung out well over four years because Tussey wanted to build me a gun with all the latest bells and whistles. I was in no hurry to get the gun, so I waited.

In this case it is true that; “Good things come to he who waits”.

What I eventually got was an absolutely reliable, tack-driving pistol that not only has the fastest sights I’ve ever used on a handgun, but it also makes full-power hardball or other hot loads feel like puff-load target ammo thanks to the compensator.

By the way, did I mention that it only weighs 19 ounces? That’s right, just 19 ounces. The standard lightweight Commander, when Colt last made them, catalogued right at 27 ounces, so that’s a half-pound shaved off an already lightweight gun.

In support of an earlier statement I think that’s pretty revolutionary.

Here’s the run-down on my new treasure.

As above, Terry started with a slide and frame from Caspian.

These are both closely inspected and measured, then Tussey works backward from these dimensions to determine how much he can take out of each piece.

The receiver is radically relieved under the back of the triggerguard, both for weight reduction and also to raise the hand in relation to the axis of the bore. This reduces felt recoil.

30 lines per-inch checkering covers the front of the gripstrap, and of course, the round-butt conversion is carefully done by hand.

One of the inherent problems with an alloy frame is that it is nearly impossible to get as smooth and slick a polish on the feed ramp as can be accomplished with a steel gun, which can affect feeding reliability. Even guns that are done properly to start can eventually get their ramps scuffed up from bullet jackets and case mouth rims.

Cutting the alloy 1911 frame for a ramped barrel solves one problem but creates another by reducing the frame strength at a critical point.

Terry’s solution is deceptively simple; just mill out the existing material and fabricate a steel insert. Of course, the doing is easier than the telling in this case, and lots of experimentation was needed before the concept worked.

What Tussey does is sandwich the alloy frame section with two steel inserts. This not only properly secures the feed ramp but it also gives additional reinforcement and a steel surface to the frame where the back of the recoil spring guide contacts it and thereby transfers the battering force of the slide to the receiver.

That prep work done, the lockworks are hand-fitted and installed using all titanium or alloy parts. A Tussey trigger job is a thing of joy, with a 4.5-pound setting feeling more like 2.5-lbs.

Turning his attention to the top end, the slide is first fitted to the frame. Then Terry attacks it with both a milling machine and hand tools to reduce the weight. Going in from the top of the slide at the rear sight, he manages to take a considerable chunk of steel out of the back of the part.

This is then filled with a machined and hand-fitted block of aluminum that restores the original contours of the slide. Mine is ribbed on top to match the Gold Cup treatment given the slide.

From there, the extractor is fit and properly tensioned and the breech face is polished to a mirror finish. Underneath, the disconnector slot is reamed so that part floats when the gun is in battery, and the rails and all contact surfaces receive a polish.

The whole upper section of the muzzle end of the slide is cut away so that the StealthComp can be fitted, and it is very hard to see the junction line between slide and compensator. The compensator is a double-vent unit with a big expansion chamber that is nearly one-inch long.

It has oval vents that measure .70 long by .35 wide each. That’s a big hole, and the two of them vent a lot of gas and make for a very efficient system, as the high-speed photos demonstrate.

The compensator is supported at all times by the end of the recoil spring guide, and when the gun is in battery you have the cone-fit of the barrel, the bottom outside edges of the comp, and the recoil spring guide all bearing upon the slide.

It’s a triple lock-up out front, and Terry coaxes the barrel lugs-to slide fit and the link-to-pin fit a little bit at a time with a high-speed hand Dremel-type tool.

For my gun Terry used a Kart National Match grade barrel, but that, along with all accessories are naturally at the customer’s discretion.

Speaking of barrels, as above the compensator eats up about an inch of the actual barrel, leaving you with a tube that is just over three inches long – shorter than an Officer’s Model.

That short barrel and the compensator don’t collaborate and completely destroy the velocity potential or consistency of ammunition though, as the Chronograph chart will show.

Tussey is also quite concise with the centering of the barrel in the slide so that it will shoot where the sights look especially at longer ranges.

Sights are a subject all their own, but the arrangement Tussey has come up writes a new chapter in the book under “fast”.

Ashley makes their own system with the “Big Dot” front and sloping “V” notch rear unit that is quite popular, but I found that I had trouble getting the front ball to settle into the crux of the “V”.

My eyes (along with the rest of me) are a couple of notches over a half-century old, and the ball seemed to “rattle” back and forth as I would try to align it with the rear.

Being much older than I, Tussey had also noticed this phenomenon. As usual he had a fix for the problem.

It turns out that Novak makes a rear unit that is a half-circle with a tritium index spot in the bottom.

Terry paired the Novak rear and the Ashley front into a hybrid system that works better than just fine – it is faster and more accurate at close range than anything I’ve tried before.

Just raise the gun, watch the ball automatically find its own way to the bottom of the half-circle as you index it over your target and squeeze the trigger.

The bullet goes wherever the ball is. The front ball also has a tritium insert in the center for night work.

Precision work is not in the cards with these sights, but I can hold two to three inches at twenty-five yards and a fifty-yard combat target takes all hits in the vital center zone when the proper hold over is learned.

At combat ranges the gun cuts one ragged hole. In fact, the accompanying photo shows the results of the first two eight-round magazines fired for the day.

I ran four double-taps to the center of mass and then four more as head shots, all as fast as I could get them out of the gun. Close examination will show eight definite pairs of holes on the target mute testimony to the accuracy of the gun and the efficiency of the compensator.

The entire pistol is “de-horned” for carry and is delightfully smooth to the touch. A flat black anodizing finishes the receiver and the gun is a two-tone thanks to the gray Diamond Coat finish on the slide.

This Diamond Coat is an industrial process that also imparts a Rockwell rating in the low 90s in addition to the handsome hue.

The lightweight StealthComp is fitted with a pair of very thin wood grip panels that appear to be walnut.

These sport eight fairly deep parallel lengthwise grooves that are as tacky to the hand or glove as checkering. I don’t know that they save any weight, but they do thin the pistol down to a svelte 1.110 inches, which is hardly thicker than the slide at .910 inches. They also contribute to the pistol’s distinctive and rakish good looks.

Completing the package is a holster from a company called Center of Mass that Terry sent along with the gun.

This is another Kydex product with a design I like, although it took me awhile to discover it. I liked the way the holster felt and was impressed with its quality, but I kept threading it onto my belt until I finally noticed it was a paddle clip.

I normally don’t like a clip or paddle, but this one sneaked up on me and taught me a lesson about keeping an open mind. It doesn’t ride up or come off, the two tensioning screws will cinch the gun in as tight as you like, and it has a huge sight channel that is perfect for the Big Dot on the gun.

The straight-drop holster rides high with a slight outward cant to the grip for near perfect presentation. It also completely shields the entire triggerguard of the pistol.

So, it took me awhile to get the gun, but I sure am glad I waited for all of Terry’s latest tricks, gadgets and gizmos. The only trouble with the guy is that he is always coming up with something new and interesting that can only be addressed by ordering another gun!

Terry will do anything from a simple Reliability Job on your 1911 (or selected other pistols and revolvers) right on through to the complete custom gun built from scratch like my StealthComp.

You can rest assured his current turn-around time is considerably shorter than four years, but check with him for the full scoop.

Terry Tussey, Tussey Custom; 24 Moonlight Rd. #A, Carson City, Nevada 89706, 775/246-1533, e-mail; TTussey45@aol.com, www.tusseycustom.com.

Holster Rick Palmer, Center of Mass Tactical; 894 N. Hwy 91, Firth, ID 83236, 208/346-6065, 208/680-2750.

VELOCITY RESULTS

Load Velocity ES SD

Black Hills 230 gr. Ball 767 13 07

Federal 230 gr. Ball 803 19 08

Federal 230 gr. HydraShok 848 20 08

Federal 165 gr. HydraShok 971 60 20

Federal 200 gr. FMJ Expanding 961 30 11

Speer 200 gr. Gold Dot HP 783 14 09

Speer 185 gr. Gold Dot HP 998 17 07

Cor-Bon 185 gr. JHP 1060 68 36

Handload: 180 gr. JHP, 9.2 gr. AA#5 948 41 16

All figures are for five shot samples as read and computed by the Oehler Model 35 Chronograph with SkyScreen III’s placed ten feet from the muzzle. ES is the Extreme Spread for the five rounds, SD is the Standard Deviation within the sample.

CAPTIONS

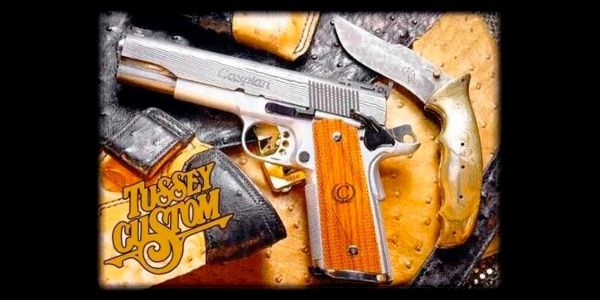

1, 2, 3 – Full beauty lay-outs of the lightweight Stealth-Comp from Tussey Custom.

4 – The Stealth-Comp with Federal’s 200 grain Expanding Full Metal Jacket ammo, which clocked almost 1000 FPS from the abbreviated barrel of the pistol.

5 – The Stealth-Comp uses a two-piece recoil spring guide that must be removed first, then it field-strips as normal.

6 – Tussey goes in here with the milling machine and hand tools to take out as much steel as possible.

7 – The underside of the slide shows the retaining bolt for the aluminum insert that is machined to match the contours of the removed steel.

8 – Balancing and tuning such a custom requires a lot of experimenting to determine spring lengths and rates. Tussey has the spring plug laser-etched to denote the use of an Officer’s Model spring in this Commander-sized pistol.

9, 10, 11 – Tussey mills out the feed ramp area of the alloy frame and replaces it with a steel insert.

12A, 12B – The Stealth-Comp uses the Ashley Big Dot with a tritium insert up front.

13 – Tussey paired the Ashley front sight with this wide-open half-circle fixture from Novak. It has a tritium index spot in the base.

14A, 14B – The Stealth-Comp is a triple lock-up in the front, getting support from the cone fit of barrel-to-slide, the edges of the slide that mate to the comp itself, and also from the end of the recoil spring plug guide rod.

15 – Hantke fired two quick magazines of double-taps to start off the day and decided that was all he needed to demonstrate the pistol’s accuracy and controllability.

16 – Here’s four from Tussey; (top to bottom) the author’s 1911 Government, the author’s new Commander Stealth-Comp, a Gold Cup converted to an Officer’s Model with round butt, and the smallest/lightest .45 ACP available anywhere. This one wears a unique Damascus steel slide from Caspian.

17 – The three different magazine sizes, including the hand-made unit on the right.

18 – Tussey not only shortens the magazine without losing any capacity, he also converts it to a removable base plate.

19A through 19G – This is the tiny custom .45 ACP from Tussey Custom. Smaller and much lighter than an Officer’s Model, the gun gives up nothing in firepower to the bigger pistol.

20A, 20B – Tussey took this Gold Cup and converted it to a round butt Officer’s Model.

DIGITAL IMAGES

Images 1 through 5 – These are not a true set of sequence shots, although they do illustrate the effect of the compensator and the lack of felt recoil with the Stealth-Comp. (Sorry we got lazy and didn’t crop number four for you.)

Story and Photos by Paul Hantke

High-Speed Photography by William Casper

April 2003